Manufactured with superior quality steel, advanced technologies, designed for use with compressed air or fluid circulation systems.

Regular and Jet circulation available.

Cutting structures allow optimum penetration rates and long runs even in the most difficult and abrasive formations.

Weight on the bit is distributed through a five part anti-friction bearing matched and ground with precision to tolerances of ± 0,0002″.

Critical areas on the external portion of the bit are protected with tunsten carbide alloy hardfacing.

- Soft

- Medium – Soft

- Medium – Hard

- Hard formations

|

DIAMETER |

CONN. |

WEIGHT |

TOOTH |

INSERT |

|||||

|

in. |

mm. |

PIN SIZE |

KG |

T3 |

T2 |

T1H |

SE54 |

SE56 |

SE58 |

|

2 7/8 – 2 15/16 |

73-75 |

N-ROD (4 thd) |

1.8 |

□ | □ | □ | □ | □ | □ |

|

3 – 3 1/2 |

76-89 |

N-ROD (4 thd) |

2 |

□ | □ | □ | □ | □ | □ |

|

3 3/4 – 3 7/8 |

95-98 |

2 3/8 API REG. |

4 |

□ | □ | □ | □ | □ | □ |

|

4 – 4 1/8 |

101-105 |

2 3/8 API REG. |

5 |

□ | □ | □ | □ | □ | □ |

|

4 1/4 – 4 1/2 |

108-114 |

2 3/8 API REG. |

5 |

□ | □ | □ | □ | □ | □ |

|

4 3/4 – 5″ |

120-127 |

2 7/8 API REG. |

5.5 |

□ | □ | □ | □ | □ | □ |

|

5 1/8 – 5 1/2 |

130-140 |

2 7/8 API REG. |

7 |

□ | □ | □ | □ | □ | □ |

|

5 7/8 |

149 |

3 1/2 API REG. |

11.5 |

■ | ■ | ■ | ■ | ■ | ■ |

|

6 – 6 1/8 |

152-155 |

3 1/2 API REG. |

12.6 |

■ | ■ | ■ | ■ | ■ | ■ |

|

6 1/4 – 6 1/2 |

159-165 |

3 1/2 API REG. |

18 |

■ | ■ | ■ | ■ | ■ | ■ |

|

6 3/4 |

171 |

3 1/2 API REG. |

18 |

■ | ■ | ■ | ■ | ■ | ■ |

|

7 7/8 |

200 |

4 1/2 API REG. |

34 |

■ | ■ | ■ | ■ | ■ | ■ |

|

8 1/2 |

216 |

4 1/2 API REG. |

38 |

■ | ■ | ■ | ■ | ■ | ■ |

When drilling hard and abrasive formations with tooth type rock bits, an excessive wear of the teeth may occur. It is necessary in such cases to use tungsten carbide insert rock bits. A specified in the next table of drilling parameters, more weight must be given when drilling with T.C.I. rock bits in order to obtain a major compression effect on hard rock being drilled.

|

ROCK BIT TYPE |

FORMATION TO DRILL |

WEIGHT PER INCH (KG) |

SPEED |

||

|

MIN |

MAX |

MIN |

MAX |

||

|

TOOTH TYPE ROCK BIT |

SOFT – MEDIUM |

450 |

1300 |

60 |

110 |

|

MEDIUM HARD |

450 |

1800 |

50 |

100 |

|

|

DURE – MOLTO DURE |

900 |

2200 |

40 |

80 |

|

|

INSERT ROCK BIT |

SOFT – MEDIUM |

450 |

1800 |

45 |

80 |

|

MEDIUM HARD |

1200 |

2800 |

40 |

80 |

|

|

HARD AND ABRASIVE |

1800 |

3100 |

30 |

60 |

|

Large Diameters New & Retiped,Rerun

For oil and water well drilling.

New and reconditioned of major U.S.A. brands: HUGHES, SMITH, REED, SECURITY.

- milled steel tooth type

- tungsten carbide insert type

Available with sealed or regular bearing, with regular or jet circulation.

|

DIAMETER inch |

DIAMETER mm. |

CONNECTION |

WEIGHT |

|

|

LBS |

KG |

|||

|

5 7/8″ |

149.2 |

3 1/2″ API REG. PIN |

29 |

13 |

|

6″ |

152.4 |

3 1/2″ API REG. PIN |

32 |

14 |

|

6 1/8″ |

155.6 |

3 1/2″ API REG. PIN |

33 |

14.5 |

|

6 1/4″ |

158.8 |

3 1/2″ API REG. PIN |

40 |

18 |

|

6 1/2″ |

165.1 |

3 1/2″ API REG. PIN |

46 |

21 |

|

6 3/4″ |

171.5 |

3 1/2″ API REG. PIN |

49 |

22 |

|

7 7/8″ |

200.0 |

4 1/2″ API REG. PIN |

76 |

34 |

|

8 1/2″ |

216.0 |

4 1/2″ API REG. PIN |

90 |

41 |

|

8 3/4″ |

222.3 |

4 1/2″ API REG. PIN |

92 |

42 |

|

9 1/2″ – 9 7/8″ |

241.3 – 250.8 |

6 5/8″ API REG. PIN |

141 |

65 |

|

10 5/8″ |

270.0 |

6 5/8″ API REG. PIN |

170 |

77 |

|

11″ |

279.4 |

6 5/8″ API REG. PIN |

175 |

80 |

|

12 1/4″ |

311.2 |

6 5/8″ API REG. PIN |

220 |

100 |

|

13 1/2″ – 13 3/4″ |

342.9 – 349.3 |

6 5/8″ API REG. PIN |

237 |

108 |

|

14 3/4″ |

374.7 |

6 5/8″ o 7 5/8″ API REG. PIN |

305 |

138 |

|

16″ |

406.4 |

6 5/8″ o 7 5/8″ API REG. PIN |

415 |

187 |

|

17 1/2″ |

444.5 |

7 5/8″ API REG. PIN |

580 |

262 |

|

22″ |

558.8 |

7 5/8″ API REG. PIN |

766 |

347 |

|

23″ |

584.2 |

7 5/8″ API REG. PIN |

820 |

372 |

|

26″ |

660.4 |

7 5/8″ API REG. PIN |

1335 |

605 |

|

28″ |

711.2 |

8 5/8″ API REG. PIN |

1600 |

720 |

Available with sealed or regular bearing , with regulator or jet circulation.

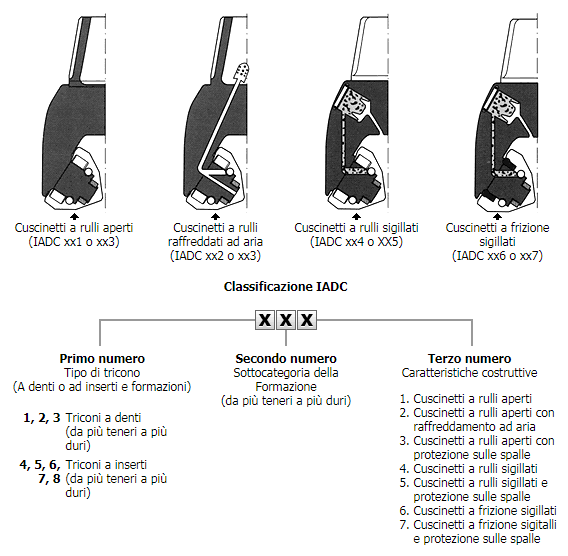

Classification – code IADC

|

Tooth Type |

|

|

Soft formations IADC CODES 111 – 126 – 134 |

|

|

Medium formations IADC CODES 211 – 224 – 234 |

|

|

Medium Hard – Hard formations IADC CODES 311 – 314 – 321 |

|

|

Insert Type |

|

|

Soft – Medium Soft formations IADC CODES 437 – 517 – 527 |

|

|

Medium Hard – Hard formations IADC CODES 617 – 627 – 637 |

|

|

Hard and abrasive formations IADC CODES 732 – 737 – 837 |

|