Dal DN100 al DN600

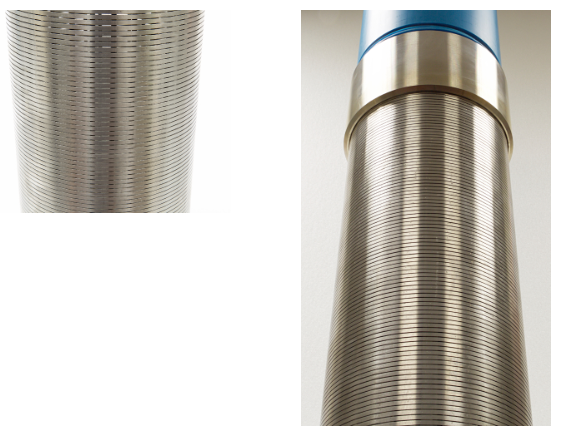

Screens are produced wrapping in continuous wire, with triangular shape, on round directress.Every intersection is resistance welding (RW).

Going through all the various combination of wire’s section,number of directress and step is possible to produce screens for many different application fitting perfectly every project.

Features

V-wire screens are characterized by a large filtering surface that gives very high performance in passage of water even in presence of low speed water.

This allows to optimize the well production:

-Minimun hydraulic resistance

-Reduced encrustation

-Less impurity (sand) that might damage the pump

-Fast and complete perforation fluid removal

Material

The product is made in high quality Stainless Steel to resist to pressure and stresses during installation or to corrosion

Dimensions and Standards specifications

From DN100 to DN600

n.3 levels of collapse pressure resistance

Configurable slot opening in base of the sand analysis

Stainless steel standard grade AISI 304L 1.4301 or AISI 316L 1.4404

Joins:welded threaded M/F (metric trapezoidal or type API)

|

DN |

Diam. est. a saldare |

Diam. est M/F |

Diam. Int Min. |

Peso Kg/mt.2 |

|

3 1/2 |

88,9 |

114,3 |

77 |

7,8 |

|

4 1/2 |

114,3 |

127 |

96,3 |

9,5 |

|

5 1/2 |

139,7 |

152,4 |

121,7 |

11 |

|

6 5/8 |

168,3 |

181 |

150,3 |

13,5 |

|

7 5/8 |

193,7 |

203 |

175,7 |

15 |

|

8 |

210 |

220 |

192 |

16 |

|

8 5/8 |

219 |

230 |

201 |

17,5 |

|

10 |

250 |

264 |

232 |

18,5 |

|

10 3/4 |

273 |

282 |

255 |

22 |

|

11 3/8 |

300 |

314 |

282 |

23,5 |

|

12 3/4 |

323,4 |

340 |

305 |

24 |

|

14 |

355,6 |

370 |

337,6 |

27 |

|

16 |

406 |

425 |

388 |

32 |

TO ORDER SPECIFY:

- O.D.

- SLOT

- Length required

- Connection (buttweld or M/F couplings)